| Case | A spring of a steam valve was broken after several years of service. Conditions steam 80 bar at 500°C. The lowest winding of the spring, located inside the bonnet at atmospheric conditions, was broken. |

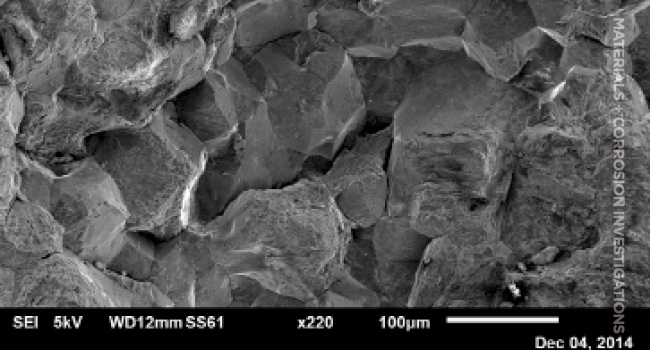

| Cause | The material of the spring was corroded near the fracture. SEM investigation revealed a typical intergranular fracture surface with pitting at the edges. The morphology is characteristic for hydrogen embrittlement, induced by the cathodic partial reaction of the corrosion process. |

| Advice | Waterproofing of bonnets and apply insulation to prevent condensation. |